Welcome to Kardio-Med Silesia Site

Silesian Park of Medical Technology Kardio-Med Silesia

is a modern research center meet the highest European standards.

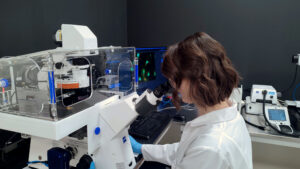

Recently, 3D printing methods have been gaining popularity both in industry and in science and medicine. The development of 3D printers and new printing methods are opening up opportunities for laboratories with such equipment. Bioprinting is gaining importance in the context of scientific research in the area of tissue engineering and in medicine in the area of personalized therapies.

Through the use of bioprinting, it is possible to produce spatial structures for cell growth that are equivalent to the natural intercellular matrix in tissues. Materials used for cellular scaffolds include hydrogels, bone cements, thermoplastics, natural or synthetic materials including composites and hybrid materials. Our laboratory has the ability to print hydrogels (fibrin, collagen, GelMa, alginate) as well as thermoplastic materials (PLA, PCL) to produce cellular scaffolds for various applications (research projects, implementation projects, tissue regeneration, research models, diagnostic models, drug testing models). We have experience in applying cells to hydrogel surfaces and printing cells directly into the volume of the material. Thanks to the printer we have at our disposal (Cellink BioX), it is possible to combine up to 3 types of material/cells (3 printing heads) during the bioprinting process. Cocultures produced in this way (e.g. cardiac muscle cells + endothelial cells) are currently a popular research model in advanced scientific research. In the laboratory, we also have microscopes suitable for imaging scaffolds (material microscope) as well as cell viability and morphology (fluorescence microscope) on the scaffold. Equipped with a rheometer, we are also able to characterize the properties of hydrogels, resins or pastes as printing materials.

Printing of anatomical models

We offer the printing of anatomical models of hard tissue based on X-ray images that can be used for educational purposes as well as scientific research or the design of medical devices, surgical procedures and experimental therapies. With the Raise3D E2 printer, it is possible to print objects and a maximum length of 330 mm using two different materials. We offer printing with different materials: PLA, PETG, PP, ABS and others.

We offer the printing of anatomical models of hard tissue based on X-ray images that can be used for educational purposes as well as scientific research or the design of medical devices, surgical procedures and experimental therapies. With the Raise3D E2 printer, it is possible to print objects and a maximum length of 330 mm using two different materials. We offer printing with different materials: PLA, PETG, PP, ABS and others.

Printing of prosthetic components and other high-resolution models

We offer printing of prosthetic models or other elements (prototypes) requiring high printing accuracy, made of technical and medical resins. The Formlab 3B printer enables 3D printing with a resolution of 80 mm at a layer height of 25 mm. It is possible to print elements with standard resins, mechanically durable resins, flexible resins, dental resins, and castable resins (castable wax).

Copyright 2023 Kardio-Med Silesia. Site designed by Daniel 'zoNE' Gabryś. All rights reserved.